How ENGEL closes the gap between the digital twin and reality

As the world market leader, ENGEL AUSTRIA GmbH develops and manufactures innovative injection molding machines for the automotive & mobility, medical technology, consumer electronics, packaging, and technical injection molding industries. However, the family-run company based in Schwertberg, Austria, sees itself as more than just a machine manufacturer; it also offers automation and digital solutions. With 6,400 employees across 85 locations worldwide, ENGEL advises its customers from the initial idea and the selection of the injection molding machine to automation solutions and process monitoring. This makes ENGEL a reliable partner in the field of injection molding.

How ENGEL Closes the Gap Between the Digital Twin and Reality

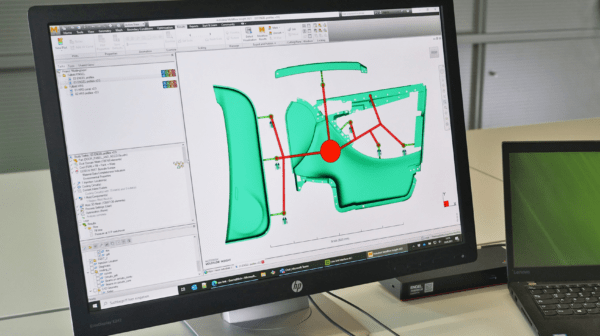

In 2018, ENGEL focused on the topic of simulation and developed the product ENGEL sim link, which allows Autodesk Moldflow users to benefit more extensively from injection molding simulation.

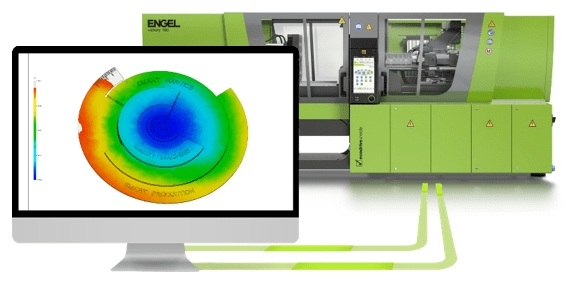

ENGEL sim link enables direct data transfer between the simulation software and the injection molding machine, thereby closing the gap between the digital twin of the mold and the real production process. Relevant parameters from the simulation can be transferred to the machine simply and automatically; conversely, measurement datasets from the machine control system can be imported back into Autodesk Moldflow.

This makes it possible to analyze machine measurement results within the simulation, providing new starting points for process optimization. In the past, Moldflow simulation results were often ignored during machine setup, meaning valuable knowledge was discarded. With ENGEL sim link, simulation expertise can now be used systematically for machine setup and process optimization for the first time. Additionally, the behavior of the specific injection molding machine can be accounted for in the simulation—a step toward even more detailed simulation.

With these individual steps, ENGEL sim link ensures complete data consistency, eliminating the time-consuming and error-prone manual entry of data at the machine. ENGEL sim link has been on the market since 2021 and is experiencing very high demand.

For the Best Possible Result in Injection Molding

„At ENGEL, we have set ourselves the goal of not only supporting our customers in the production of an injection-molded part but offering them the most efficient and best possible result throughout the entire product cycle using digital solutions. One step in this product life cycle is simulation. We saw potential for improvement here by transferring information that already exists in the virtual world to the machine. That is how the idea for ENGEL sim link was born,“, explains Dr. Johannes Kilian, Head of the Department for Process Technologies and inject 4.0 at ENGEL

However, the company also faced challenges: “Digitalization must not stop at new machines. ENGEL sim link is not just intended for new equipment; it also targets almost all of the more than 90,000 ENGEL machines already running in our customers’ production halls. Developing a product aimed at the existing market is very complex and time-consuming because you have to take many specifications into account. At the same time, we were initially a bit hesitant, especially regarding the topic of simulation vs. reality. But together with MFS, we have created excellent use cases that demonstrate that the customer truly gains concrete added value through ENGEL sim link,” says Dr. Johannes Kilian.

Strong Partnership with MF Software

The Autodesk Gold Partner MFS supported ENGEL from the very beginning with support, training in Autodesk Moldflow, and marketing. “We decided on Moldflow as our simulation software and then reached out to MFS because they are an experienced Autodesk Moldflow service and sales partner in Germany. Since then, a very strong partnership has developed. We are in continuous contact with MFS whenever it comes to diving into the depths of simulation. I view the collaboration very positively,” says the head of department, describing the partnership with MFS.

Autodesk Moldflow – The Leader in the High-End Segment

The choice of simulation software fell to Autodesk Moldflow because it is the most widely used software for injection molding simulation in the high-end sector, he explains. “We want to create the link between simulation and reality, and we naturally rely on the simulation program that our customers actually use and that is the most prevalent in the market.”