MFS Customer Success Stories

See for yourself the experiences of our existing customers

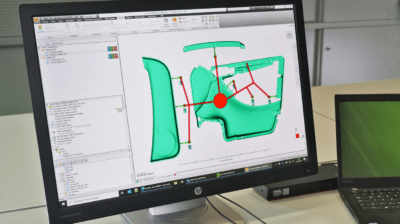

Whether during school, at the office, or in our free time – many of us have held a fountain pen, ballpoint pen, or pencils from the German market leader LAMY in our hands. Globally, the LAMY brand stands for high-quality, timeless designer writing instruments with perfect functionality. This is evident right from the manufacturing stage. The most important parameter, immediately following actual function, is compliance with high requirements for aesthetics and dimensional accuracy for the tight-tolerance individual parts. To achieve this and to identify problems in the component at an early stage, LAMY relies on injection molding simulation with Autodesk Moldflow.

Many of us wear them on our feet every day: shoes from adidas, Nike, PUMA, or New Balance. However, very few people know the important role that framas Kunststofftechnik GmbH plays in the creation of these sports shoes. The Pirmasens-based company develops and optimizes plastic components for the shoe and technical injection molding industry using Autodesk Moldflow.

inpro – the Innovation Company for Advanced Production Systems in the Automotive Industry – has been developing innovative technologies and software solutions for industrial production and engineering processes for 40 years. Headquartered in Berlin, this joint venture between the industrial groups Volkswagen and Siemens stands at the intersection of science and business and pursues a vision of seamless digitalization for the automotive industry—from product design through to operational production.

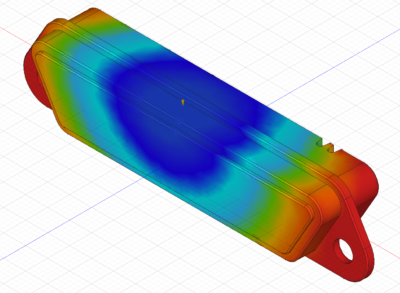

Signal-Construct GmbH produces a wide range of innovative, LED-based products and assemblies for renowned customers in the electrical, electronics, equipment and mechanical engineering sectors, as well as the rail and avionics industries. The company manufactures the plastic housings for its products in-house using the injection molding process. Quality and precision are top priorities throughout this process

As the world market leader, ENGEL AUSTRIA GmbH develops and manufactures innovative injection molding machines for the automotive & mobility, medical technology, consumer electronics, packaging, and technical injection molding industries. However, the family-run company based in Schwertberg, Austria, sees itself as more than just a machine manufacturer; it also offers automation and digital solutions. With 6,400 employees across 85 locations worldwide, ENGEL advises its customers from the initial idea and the selection of the injection molding machine to automation solutions and process monitoring. This makes ENGEL a reliable partner in the field of injection molding.