MF Software exceeds even the highest requirements through injection molding simulation

Drägerwerk AG & Co. KGaA, an internationally leading company in medical and safety technology, approached MF Software (MFS) with high requirements for a cable duct. Following successful process optimization, Drägerwerk received a component that even exceeded expectations in terms of accuracy and surface quality.

Challenge: Accuracy and Minimization of Warpage

The cable duct to be optimized was a rectangular plastic component with a lid, used in hospitals in intensive care units and patient rooms to conceal cables from machines or monitors. “This component had to be very straight, and the lid had to fit exactly to ensure that it could be hygienically cleaned. No gaps or edges were allowed to form where bacteria could settle. This means there was very little tolerance during production, and the warpage had to be near zero,” says André Hau, technical sales representative at MFS, describing the requirements.

Since plastics generally tend to warp or slightly lose their shape, this was a major challenge. Therefore, Drägerwerk turned to MFS, who supported the company through project coaching in process and component optimization. MFS trained the employees using the current project on how to approach and efficiently solve such problems using Autodesk Moldflow software.

Through many years of cooperation with major medical technology suppliers, MFS was familiar with the special requirements for components in medical technology—such as warpage minimization, sterilizability, surface quality, strength, or durability—and was able to provide Drägerwerk with expert advice on this project.

“Looking into” the process through simulation

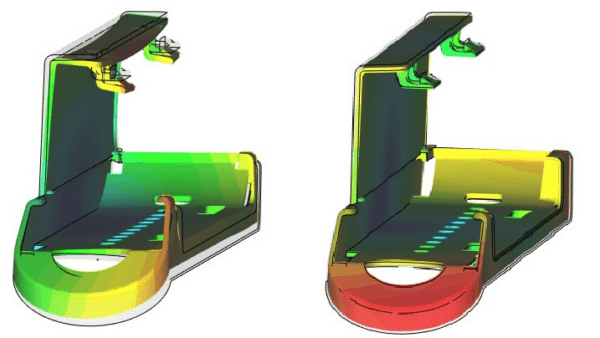

The goal was not to minimize warpage superficially but to look deeply for its causes. Such “looking into” the tool and the process is only possible through simulation. Therefore, the actual state of the production machines was first simulated in Autodesk Moldflow and potential for improvement was identified, before finally optimizing the process settings through further simulation loops and summarizing the simulatively optimal result in the form of a catalog of measures.

Expectations even exceeded

After Drägerwerk completed the optimization and redesign of the tool, taking the recommendations into account, the produced cable ducts even exceeded expectations. “The deformations in reality were even lower than what we had calculated in Moldflow. Now the customer has a component they are very satisfied with,” says André Hau.

“We have now received cable ducts that have exceeded our expectations—in terms of dimensional accuracy and surface quality.” Drägerwerk AG & Co. KGaA

Software and consulting from a single source

MFS is a solution provider that develops strategies for injection molding simulation with Autodesk Moldflow tailored to the individual needs of its customers. 30 years of experience and over 17,000 projects in the field of injection molding simulation make MFS a specialist in this field. The employees and trainers at MFS are trained plastics engineers who have deep technical background knowledge of the injection molding process for plastic components. Depending on the application, they recommend the right software solutions and offer various services:

- Training and Support: MFS trains companies so that they can work independently with Autodesk Moldflow. This includes not only the functions of the simulation software but, above all, the knowledge of the procedure for process optimization and efficient problem-solving. This enables companies to successfully establish injection molding simulation in-house and thus save time and costs.

- Strategy Consulting: Based on customer requirements, MFS creates a strategy identifying which software expansion level of Autodesk Moldflow is the right one, how many licenses are required, and how many employees need to be trained in what way to achieve the highest possible efficiency within the shortest time.

- Project Coaching: For specific questions regarding process optimization during the development of plastic components, MFS assists its customers with advisory project coaching.