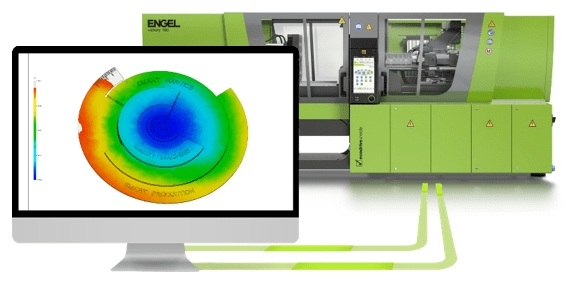

Simulation combined with the real world

On the occasion of K 2019, ENGEL announces that it is breaking new ground in the further digitalisation of the injection moulding process in collaboration with Autodesk. The aim is to link the simulation with the real process, in order to be able to better support the plastics processor throughout the complete product life cycle – from product development and tool design through to production. At the K trade fair, which takes place in Dusseldorf from October 16 to 23, exhibition visitors can see for themselves how, with the help of ENGEL sim link, the results of simulations performed using the Moldflow simulation software from Autodesk can be transferred to the CC300 control of the ENGEL injection moulding machine – and how process and measurement data can flow back from the machine for use in the simulation.