Plastics and injection moulding trainings beyond the software

Under the name MF Academy, we offer advanced, application- and process-oriented in-depth training courses. For some of these training courses, we work closely with industry partners, so the content of these courses goes far beyond Moldflow application and result interpretation.

- Student Trainings

- Process-related Trainings

- User-related Trainings

- Project Coaching

- Mechanics related Trainings

New: Our Free Student’s Training

***Fully Booked***

Prerequisites:

Basic theoretical knowledge in the fields of plastics processing (especially injection molding technology) and materials engineering, as well as basic knowledge of thermoplastic properties, are required. Preferred fields of study include plastics engineering, process technology, materials science, and mechanical engineering with specializations in toolmaking or plastics engineering.

Duration:

5 days

Content:

- Introduction to Synergy

- Meshing, meshing criteria and meshing tools

- Material data in Moldflow

- Injection point determination

- Process settings (filling, packing pressure, warpage)

- Interpretation of simulation results & Autodesk Moldflow Communicator

- Gating systems

- Fiber orientation

- Differentiation of shrinkage and warpage

- Influence of the design

- Types of warpage analysis

- Causes of warpage

- Optimization possibilities

- Shrinkage compensation

- Types of cooling calculation methods

- Consideration of mold inserts

- Modeling of cooling systems

Price:

Free / Prior registration and attendance to the introductory webcast and proof of student status are required / We reserve the right to refuse registrations without providing a reason

Process-related Trainings

User-related Trainings

Advanced Gating

In this joint training session with HRS and Beaumont Technologies, learn about the latest runner technologies (both hot and cold runner) and how to simulate them in Moldflow to visualize and validate advantages and disadvantages.

Interpretation Workshops

In this one to two day workshop you will also learn how to interpret the results of your colleagues, customers or suppliers as non-Moldflow users. In addition to a general workshop, we also offer customized training for divisions and departments such as process technicians and machine setters.

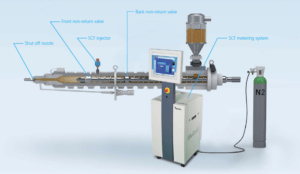

Tool Cooling

In this training you will learn about the advantages of complex tool cooling from conformal to variothermal and gain an understanding of the different possibilities to simulate them (average vs. transient, BEM vs. FEM, etc.).

Project Coaching

We offer all our (Moldflow-)trainings to small groups (up to two to three persons) also as Project Coaching. With this type of training, participants do not learn the contents by means of many small exercises, but on their own complex parts or tools.

Project coaching thus offers a perfect compromise between training and a commissioned service, as the participants learn directly from their projects and at the same time the actual project business does not stop during the training. Instead, participants return from the training with a part or tool that has been optimized together with our project engineers.

Material Trainings

Influences of Material Data on the Result Accuracy of Simulations

Learn in this training the influences of isotropic and anisotropic materials and their material data on the simulation. Especially for injection molding simulations, the quantity, the accuracy, the time of determination, material measurement methods and many other factors play a major role. In the course of this training, you will be able to check material data sets and simulations for plausibility and perform optimizations on components and molds much better.

Mechanics related Trainings

Introduction to Integrative Simulation

In this course you will learn the causes and meaning of anisotropy and how it can be taken into account in structural mechanics simulation using suitable software and material models.

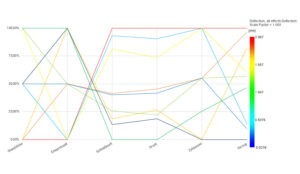

Interpretation Workshop for Structural Mechanics

In this workshop you will learn methodical rules for the behavior of parts under various load cases. Within the workshop results of the FEM simulation are visualized, interpreted, checked for plausibility and compared with reality.