Topology-optimized designs using AI

What’s Autodesk Fusion Generative Design?

With the Autodesk Fusion Generative Design functionality, your team can perform weight- or strength-optimized designs using topology optimization (AI-based). This provides the ability to create a wide variety of designs in a very short time, without the need for complex inputs and powerful computers. The software is cloud-based and can take into account a wide variety of constraints – from 3D printing to injection-molded parts.

The following are examples of steps that the Generative Design feature can take to help you reduce part development time and develop creative, modern designs.

Advantages of Fusion Generative Design

Improved product performance through generative design

Create novel designs that feature weight reduction, improved structural integrity and longer life.

Increased productivity with generative design

Generative design takes advantage of machine learning and artificial intelligence to implement even more design ideas even faster.

Reduction of all product costs

Identify generative design solutions for component protection, minimized material usage, and the cost of various manufacturing methods.

How does Generative Design work?

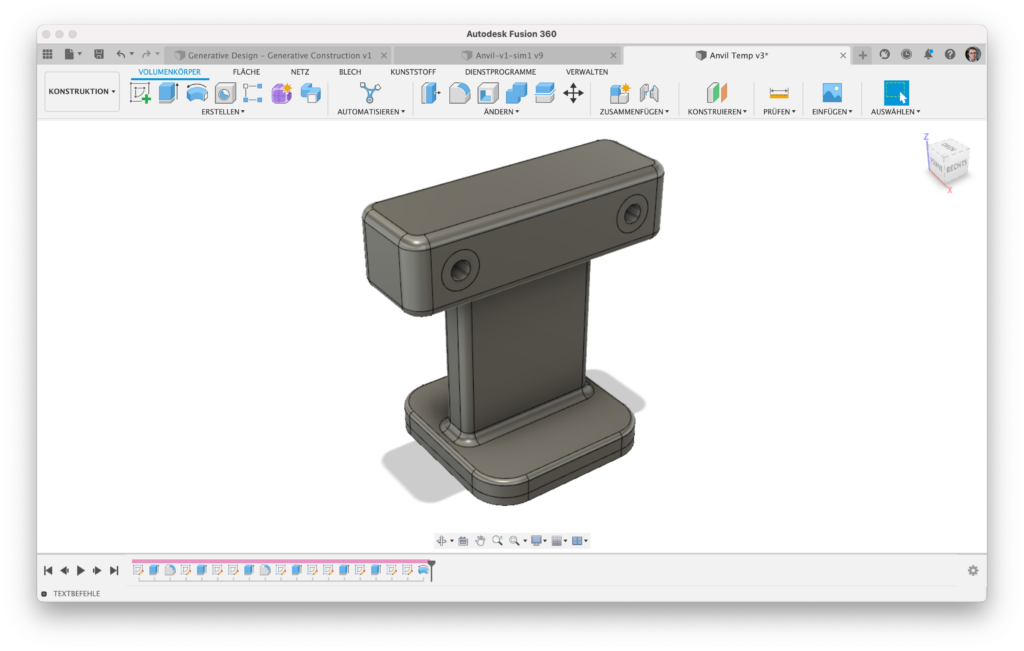

Construction of the black box

At the beginning, a simple geometry can be generated via the CAD features in the software – this represents the generally available installation space.

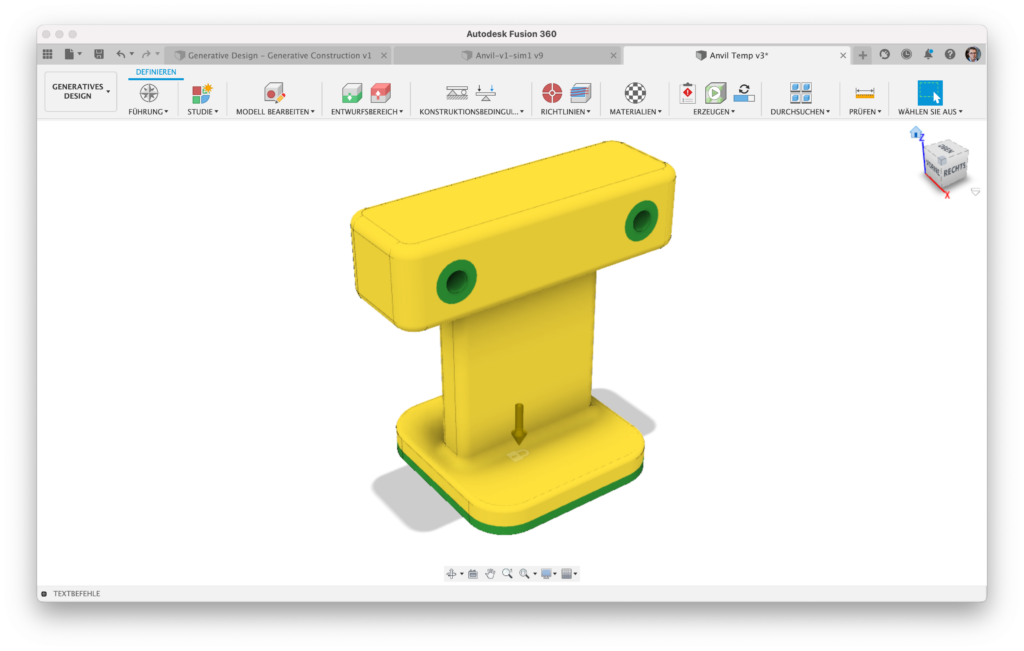

Construction of further boundary conditions

In addition to the start geometry, bodies can also be defined on which the bearing and load conditions are defined, which then provide the basis for the topology optimization (green areas contain loads and bearings, yellow the start geometry).

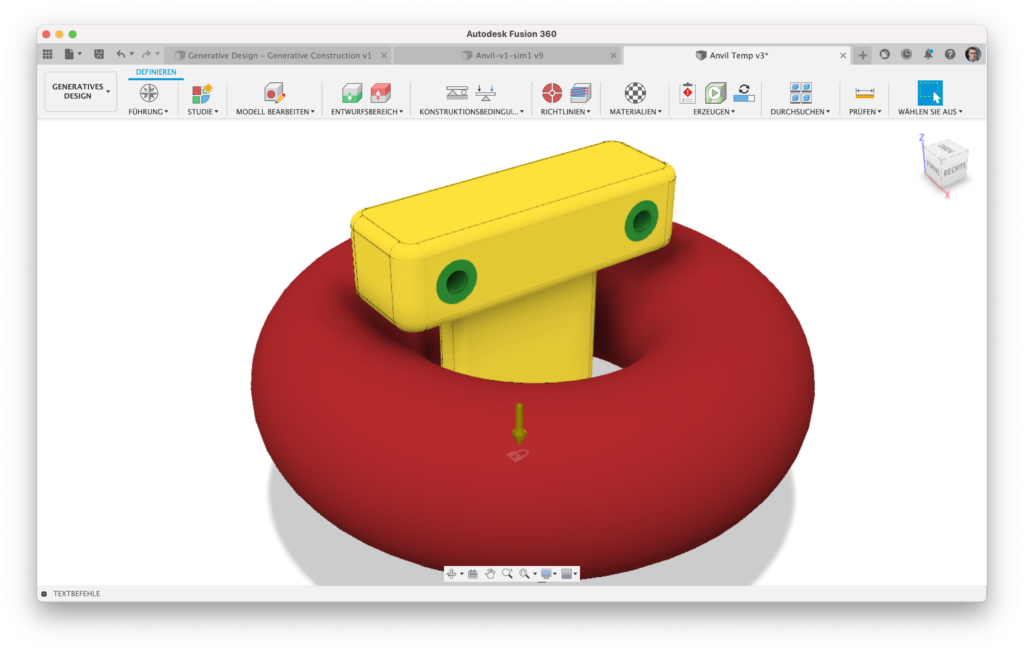

Creation of obstacles

If certain areas are definitely not to be used as black boxes, they can be defined as obstacles. These can be, for example, other components in a construction (here, the component marked in red as an example).

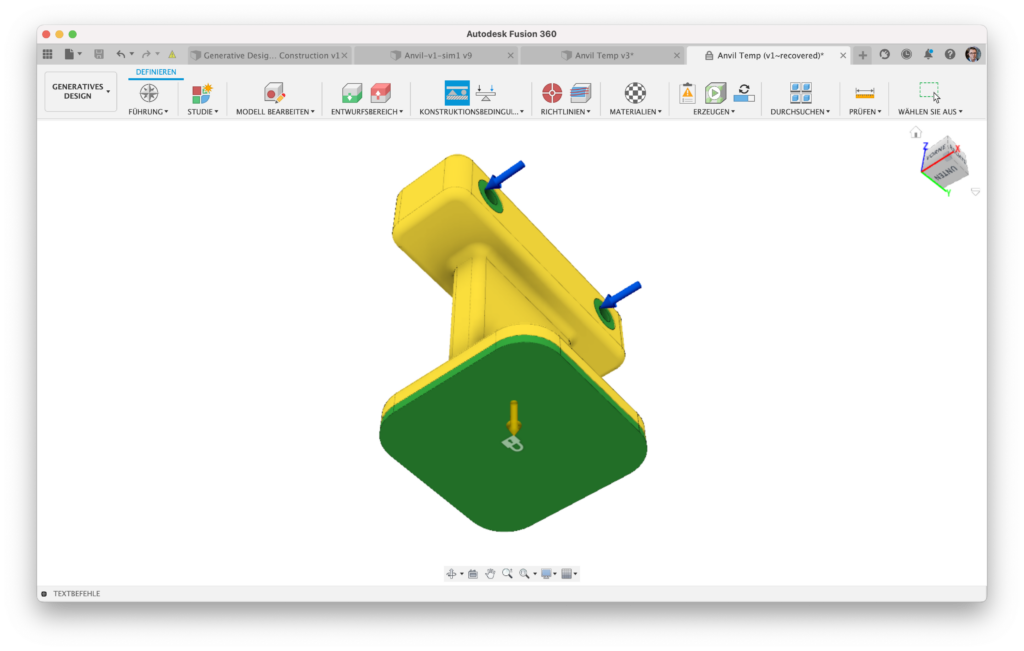

Definition of loads and bearings

As shown in the example picture, bearing surfaces or points and loads can be specified. This can be defined by simple point forces or area forces, moments or many other possibilities.

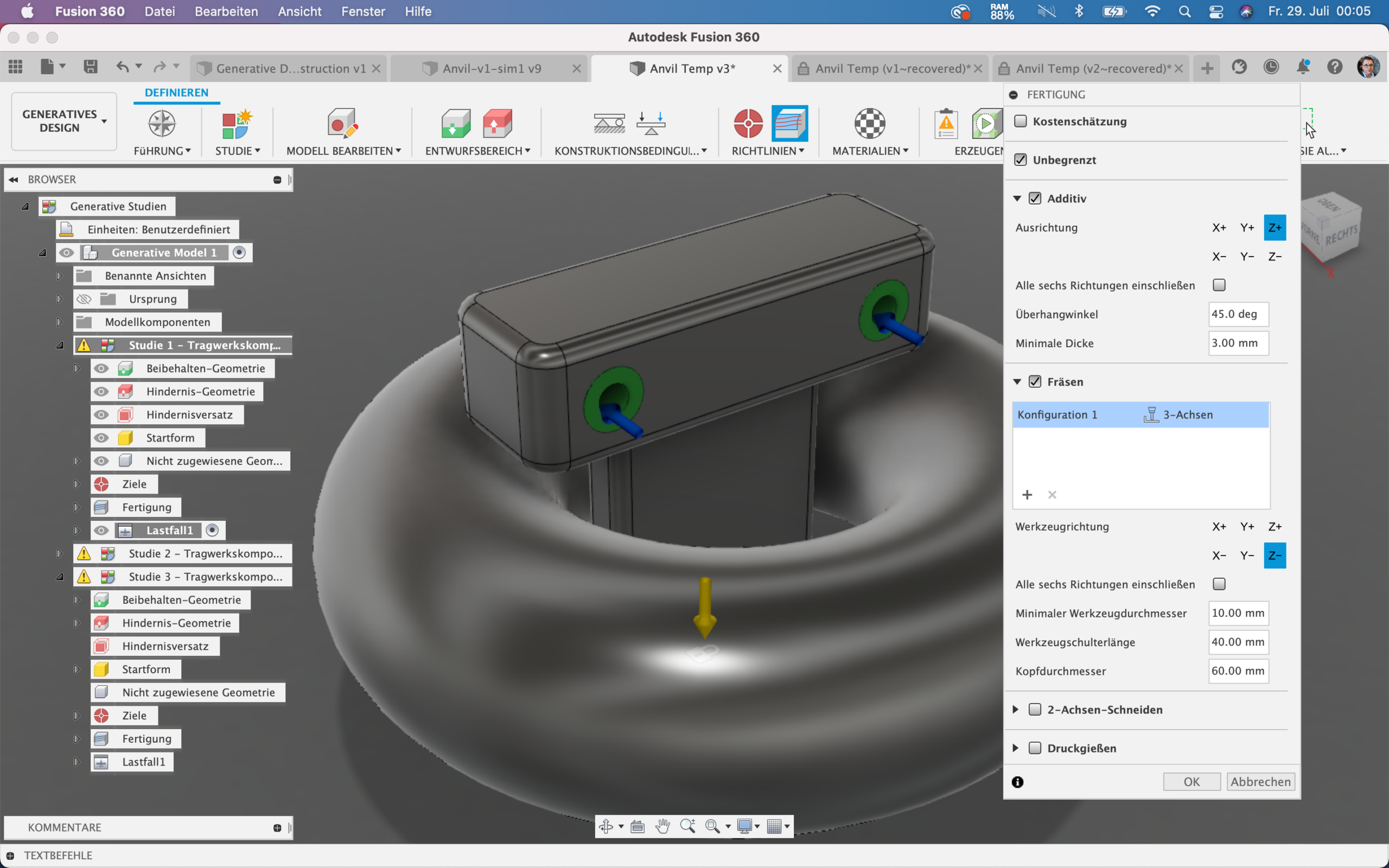

Definition of the goals and manufacturing methods

The geometries can be optimized according to stiffness or weight. In addition, one or more preferred materials can be selected. This is followed by the selection of the manufacturing methods – so far these include additive, up to 5-axis milling and, in the preview, die casting or injection molding.

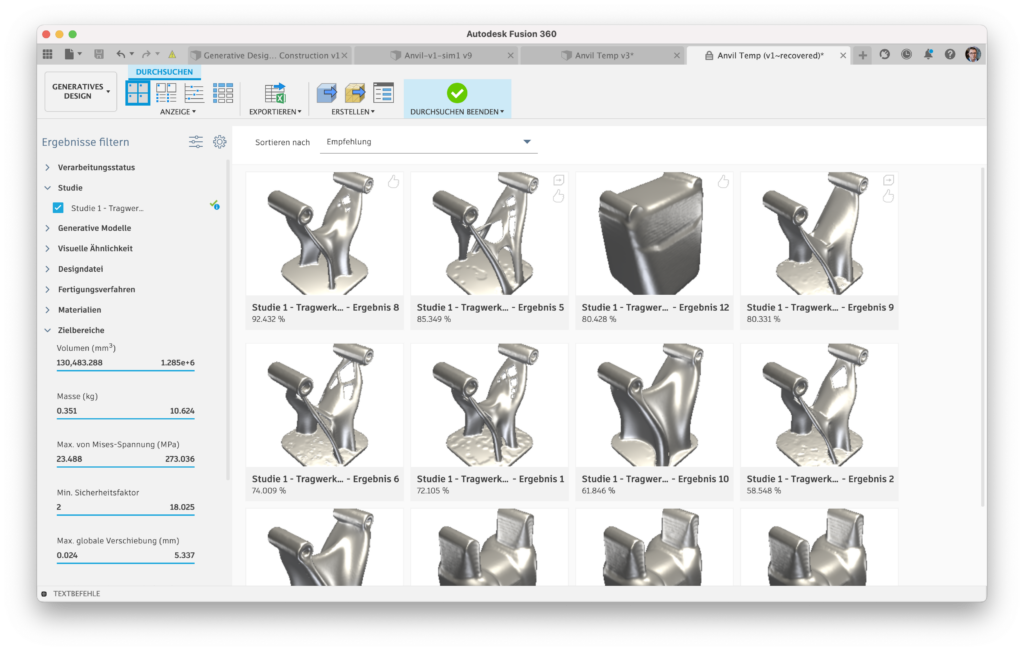

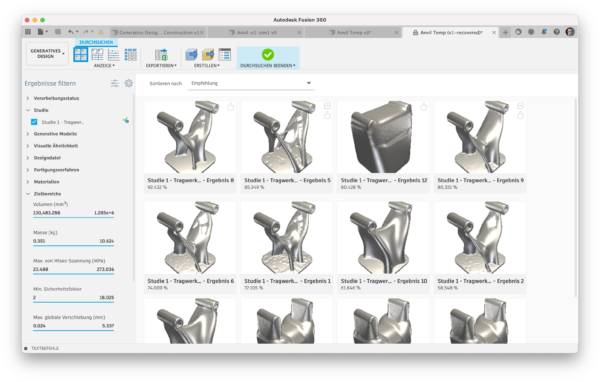

Generation of the different designs

Various design options are then calculated fully automatically on the basis of all boundary conditions. After just a few minutes, it can be observed how the different algorithms follow different shape formation approaches and generate designs for every manufacturing and material combination.

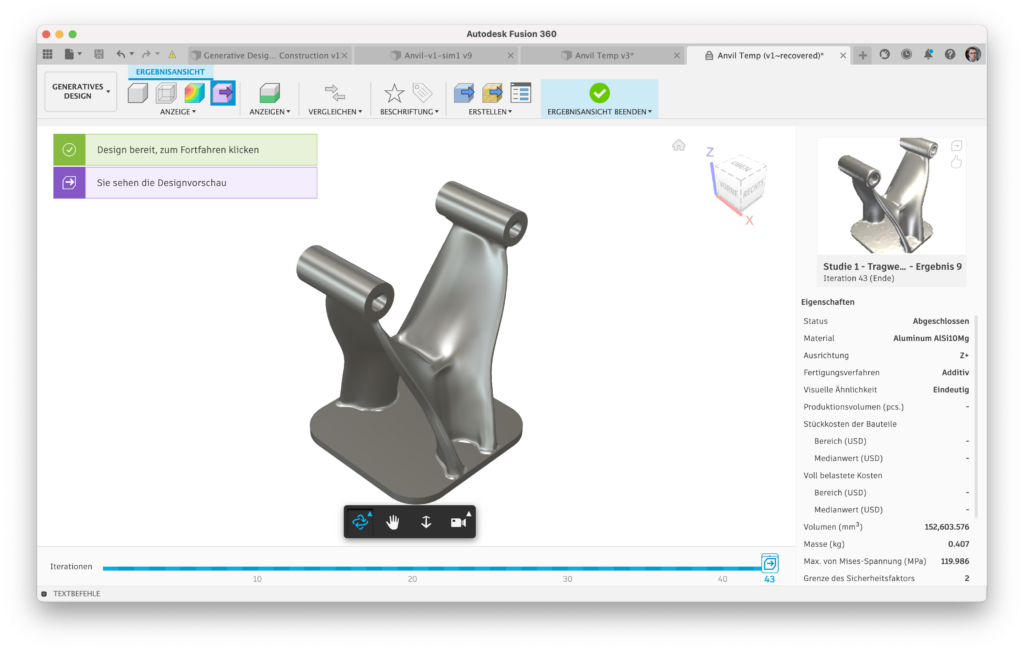

Selection of one or more generative designs

Afterwards, the generated designs can be transferred directly into a surface model – this process takes a few seconds. Surface models can be created from all generated designs and used further. The results can also be compared with each other using a wide range of evaluations.

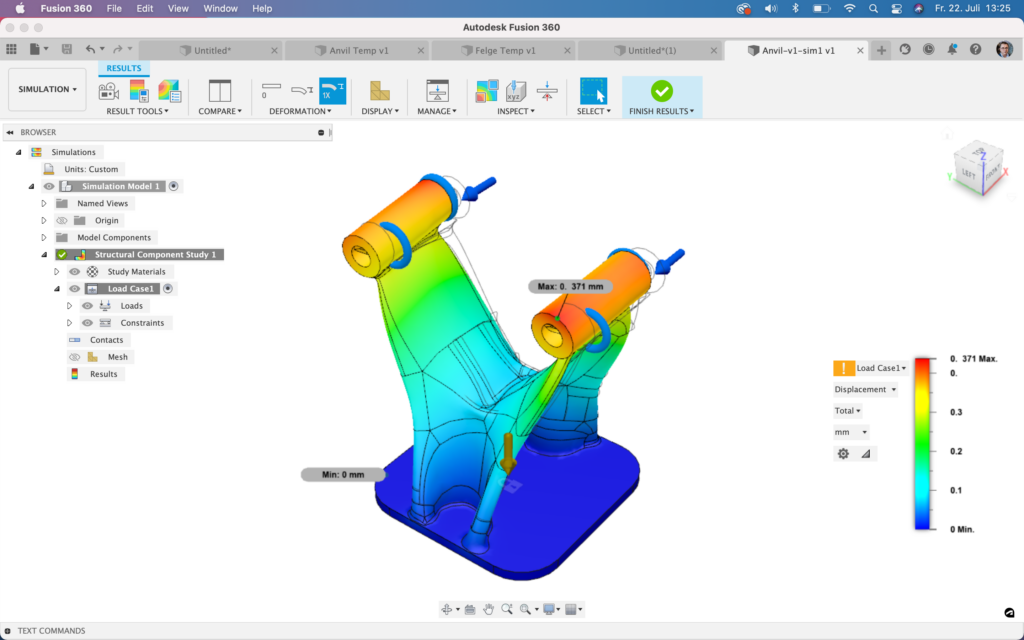

More options in Fusion after the design creation

A wide range of Autodesk Fusion functions can then be used to check the suitability of the different designs. For example, the simulation features of the Simulation Extension is ideal for analyzing the different geometries in terms of their strength, fillability or warpage, and for making further optimizations.

State-of-the-art visualization options in one place

3D rendering is the process of using computer software to generate an image from a model. Rendering is used in countless industries and application areas: architecture, simulators, computer games, special effects in feature films and TV productions, or even for visualizing designs.

By loading this video, you agree to the privacy policy of Youtube.

- - Topology optimization

- - 2.5, 3, 5-axis milling

- - Metal and injection molding

- - Observed wall thicknesses and draft angles

- - 3D printing (additive)

- - Countless design algorithms for new products

*Prices excl. VAT

Return to the Autodesk Fusion main page

Autodesk Fusion and Product Design & Simulation Extension Overview

By loading this video, you agree to the privacy policy of Youtube.