Reduce errors and costs with injection molding simulation from the Plastics Engineering Group by MFS

Why do I need injection molding simulation?

With the help of injection molding simulation, design issues, optical defects or dimensional accuracy problems in plastic components can be detected at an early stage and rectified in time. For over 30 years, our Plastics Engineering Group by MFS has been simulating and optimizing plastic components and supporting companies in the implementation of their designs and tools.

Advantages of injection molding simulation with the Plastics Engineering Group by MFS

High-precision simulations based on many years of experience and application of the latest software

You send us your CAD data and we do the rest for you. From model preparation, to meshing, to actual injection molding simulation incl. optimization of gating points, cooling channels and process parameters and the final selectable documentation, we deliver everything from one experienced source.

Fast and uncomplicated communication and processing of your plastics projects

We discuss the requirements for your plastic components with you in flexible meetings and keep you informed of progress. Before the completion of each injection molding project, we check the achievement of objectives and present the results of our simulations to you.

Simulation and optimization of injection molded parts based on your specific criteria

The targets are often as individual as each plastic component itself. That’s why we don’t have a project process according to narrow rules, but much more according to your very own criteria. We are happy to tailor our working methods to your needs. Conversely, we can also standardize with you and for you.

Contact us or send a request

Arrange individual project inquiries or framework agreements with us

For example, fast and efficient classification of requests according to 3-5 complexity levels or documentation categories.

Feel free to contact us about this possibility.

What are the possibilities in injection molding simulation / injection molding simulation?

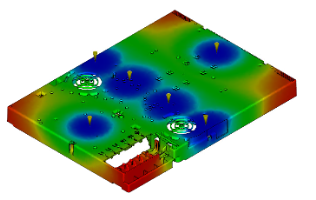

Gating concept

- Determination of optimal gating points

- Balancing of the feed system

- Minimization of pressure

- Design of cold and hot runner systems

- Optimization of fillability, filling and flow rates

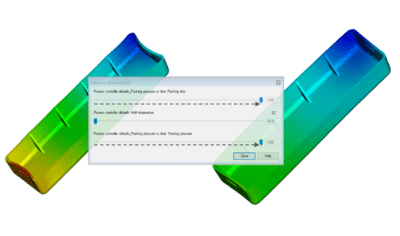

Process optimization

- Minimization of warpage

- Packing pressure optimization

- Clamping force reduction

- Alignment of fiber orientation

- Advice on wall thickness and plastic design

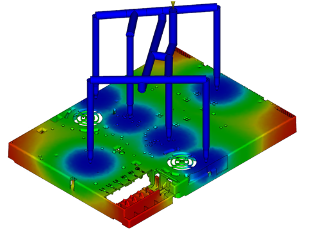

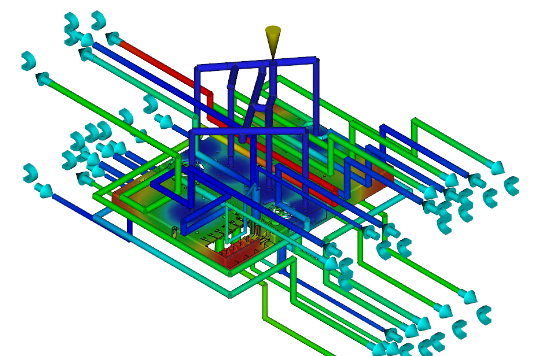

Cooling / mold tempering

- Design of the cooling channels

- Conformal cooling

- Variothermal cooling

- Cooling concept comparisons

- Optimization of the design with regard to cooling deficiencies

- Cycle time optimization