How to evaluate Shear Rates in Moldflow!

My wife and I both work from home. I told her that I didn’t have a Moldflow Monday topic picked out and she said “Do one on Shear Rate, you always talk about that when you are on customer calls or teaching an online class”. So this week – let’s talk about Shear Rate!

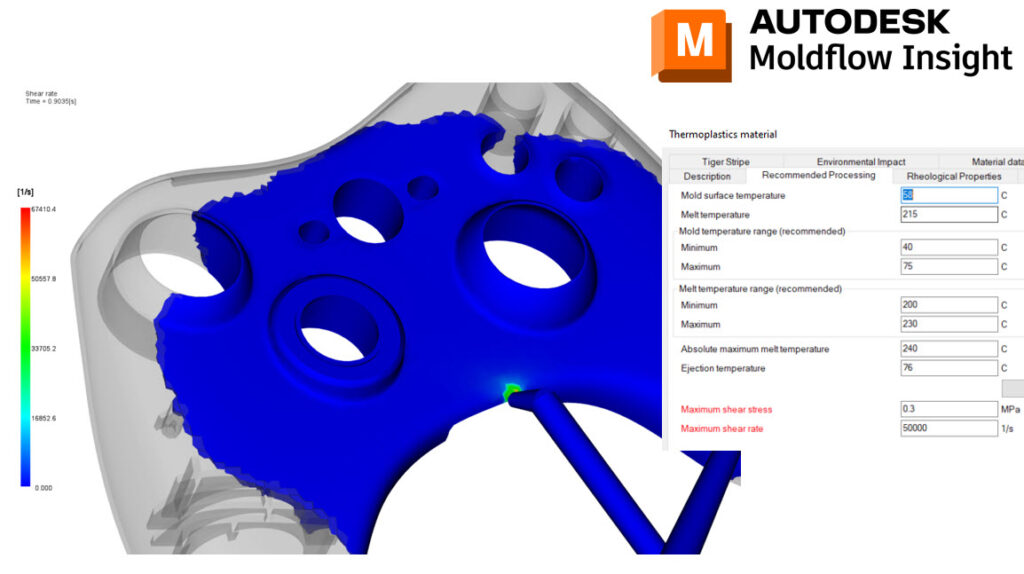

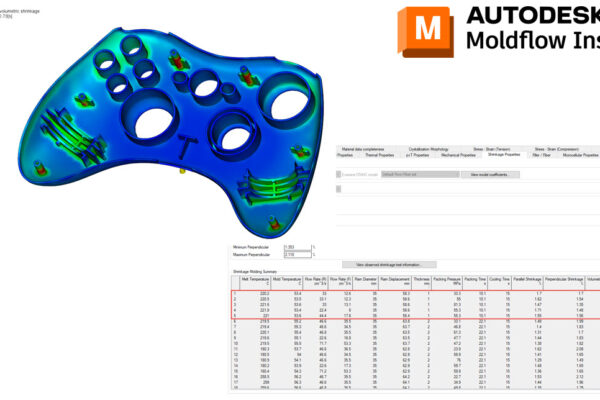

If you pick your material from the Moldflow database – the Details page will contain some general shear rate values. I use these as a guide to help size my same gates and runners. High shear rates can lead to cosmetic issues and material degradation.

If you are exceeding the shear rates in your part or gates, you can increase the wall thickness or gate size or slow down the injection speed. The same changes in gate sizes will have large impacts on shear rates and pressure.

How do you evaluate Shear Rates in Moldflow?