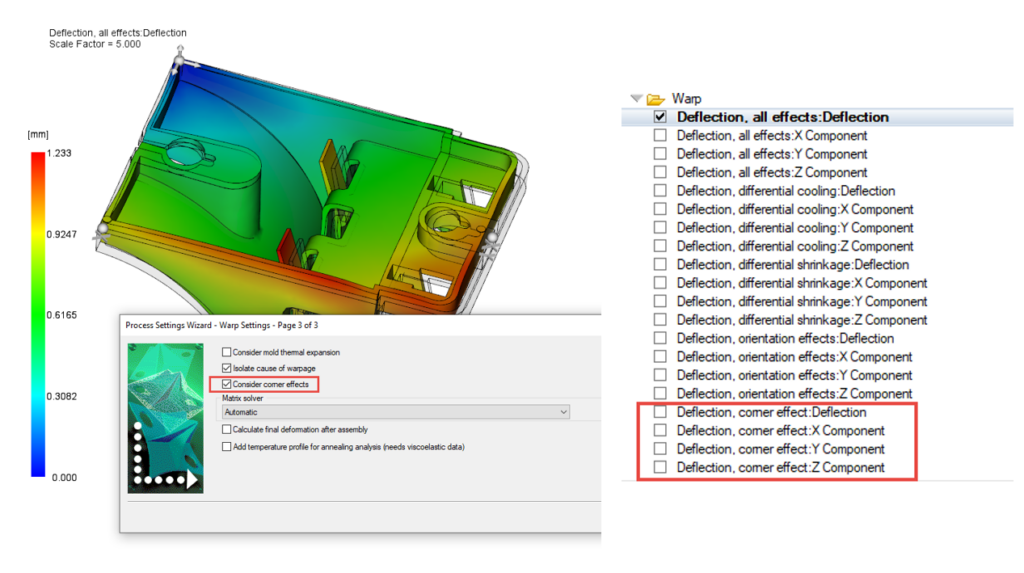

Corner Effects – what does that option do and when should we use this option?

First off, Corner effects are only available when running a Warpage analysis in Midplane or Dual Domain. This option should only be used if we have a box-shaped part. This is different from the option to simply Isolate the Cause of Warpage since this will change (usually increase) the overall Deflection, all effects.

Since we use planar triangles in Midplane and Dual Domain, it can be difficult for them to capture the bending of the side walls that we often see on box-shaped parts. Using this option will produce more accurate warp shapes in the side areas.

If Corner Effects are your main factor when it comes to warp, we should think about changing the part design or adjusting the packing. Cooling may also help but normally this would show under the Differential Cooling category.

Some of you may know that I am an unapologetic fan of 3D mesh. If I have a box-shaped part, I usually run it in 3D as well as Dual Domain (with Corner Effects). I have found that Dual Domain (with Corner Effects) can be slightly better at predicting these warp shapes from these box-like part geometry.

Have you ever used Corner Effects?