Let’s talk about 2-Shot Sequential Overmolding

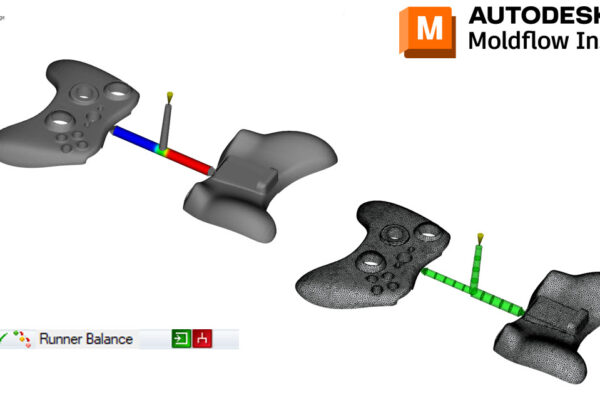

2-Shot Sequential Overmolding is 2 different materials/barrels being injected into the same mold. Shot 1 (Material A) is injected into the mold, the mold indexes or rotates, and Shot 2 (Material B) is injected around Shot 1. During this time, Shot 1 is also being injected, then the cycle repeats.

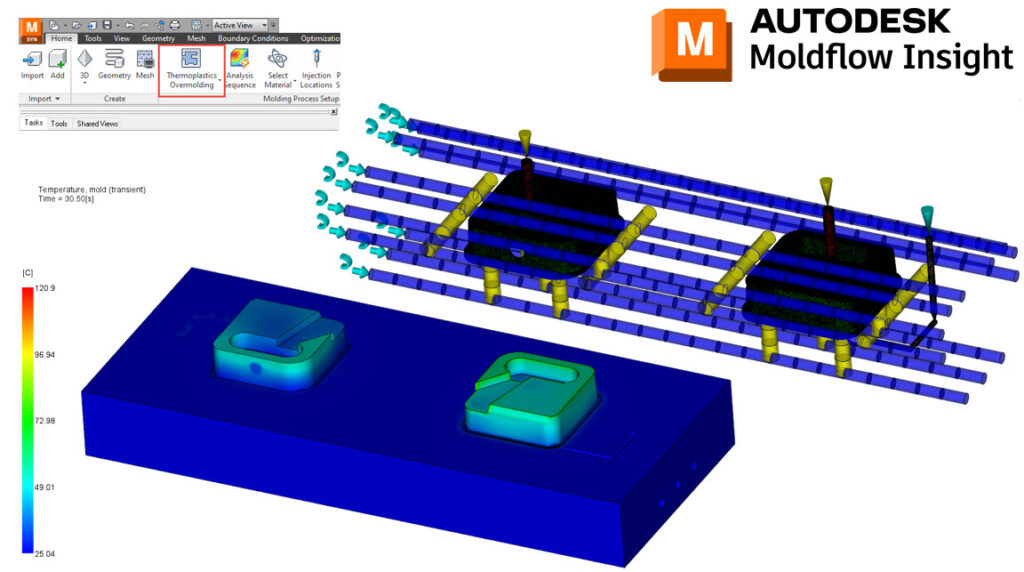

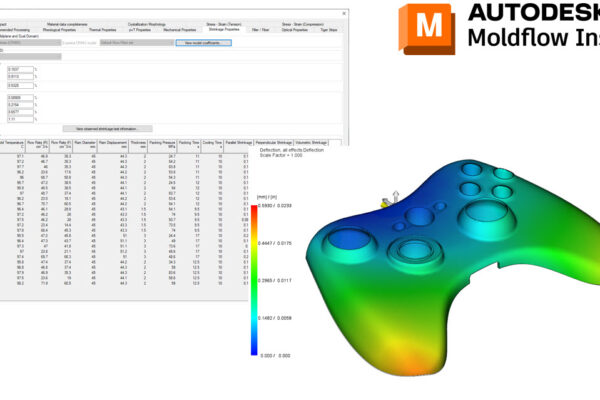

First, you need to change your analysis type to Thermoplastic Overmolding. Then you can select your analysis sequence. Setting up a Fill + Pack + Overmolding Fill + Overmolding Pack + Warp is quite easy and similar to setting up a traditional Fill + Pack + Warp. You need to assign the meshed bodies as Shot 1 and Shot 2, pick your materials, and process settings.

If you would like to run Cooling, you need to use CoolFEM and you have to model both Shot 1 and Shot 1 + Shot 2. You need to assign your cooling and mold halves to either be stationary or rotating based on the mold action.

Have you ever run a 2-Shot Sequential Overmolding?