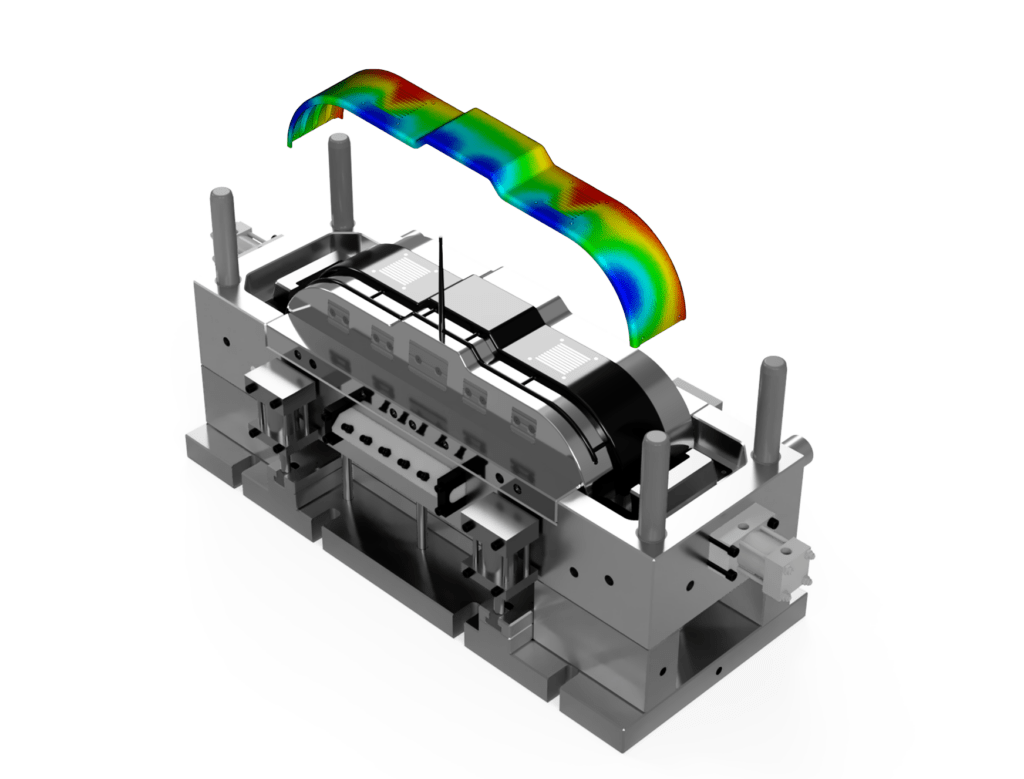

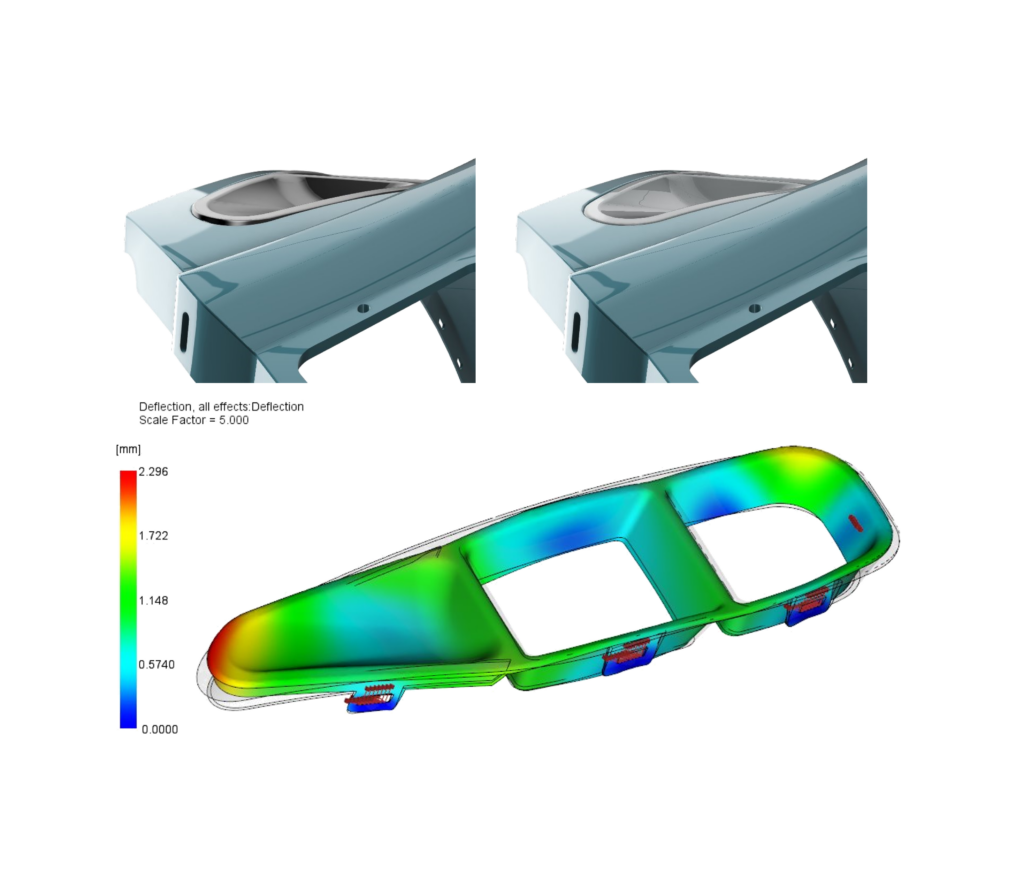

The new Autodesk Moldflow 2024 version introduces several advancements in the field of warpage optimization. This includes the new STAMP model, which relies on real shrinkage values for more accurate 3D warpage analysis. Additionally, there are further enhancements in dual domain warpage analyses, along with the introduction of a brand-new assembly analysis, allowing for warpage simulation in the context of real assembly conditions.

The New Features within Moldflow Insight 2024

Assembly Analysis (Shrinkage Adjusted Constraints)

STAMP Model in 3D

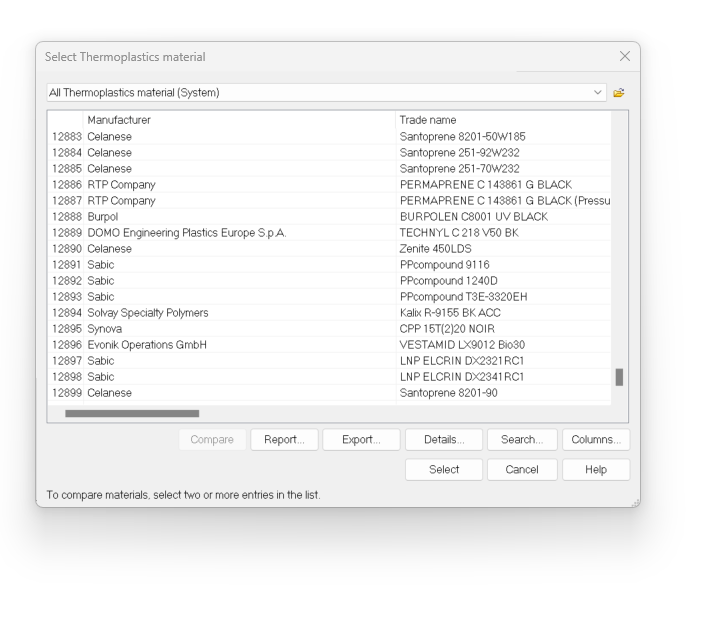

Realtime Material Database

Optimization of the molding window and automatic injection time

In particular, the default values for the Molding Window Analysis tool have been optimized for more realistic process settings, as well as an adjustment to the algorithm for more accurate automatic injection times.

Consideration of anisotropic viscosity & thermal conductivity

Consideration of the anisotropic effect of fiber orientation on polymer thermal conductivity and rheology in 3D analyses.

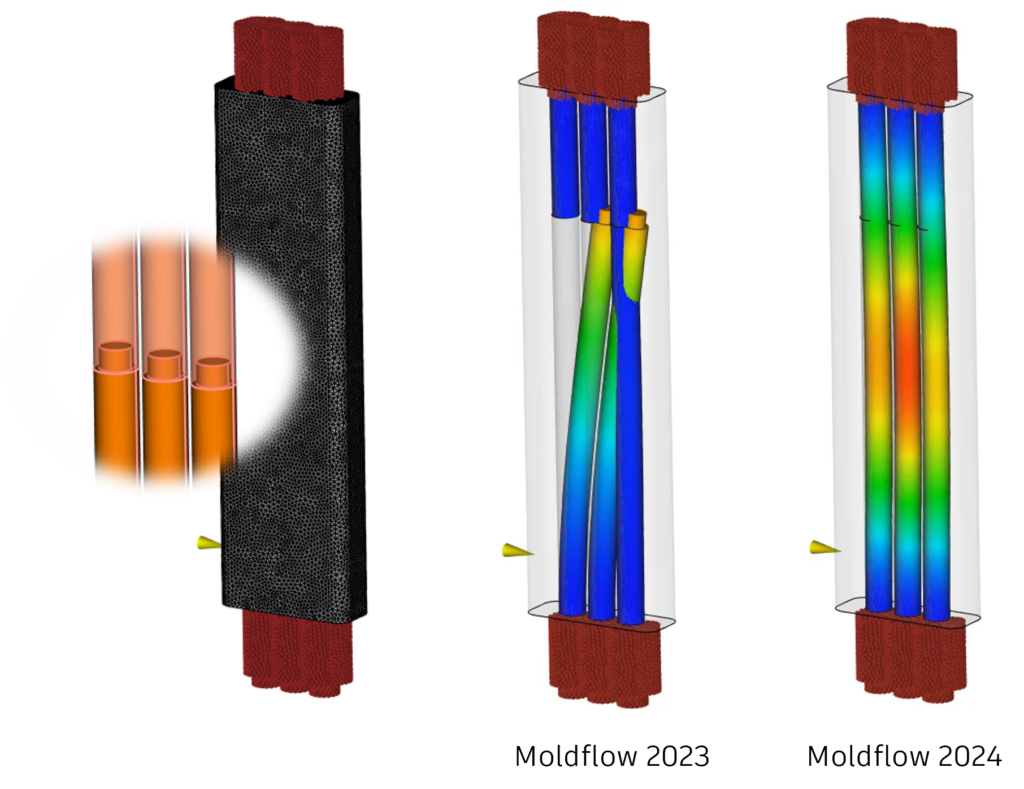

Valve gates for 3D elements

From now on, beam elements are no longer required to assign settings for valve gate nozzles. These can now also be assigned to 3D elements. This means that special channel geometries such as oval hot runner nozzles can also be simulated much more accurately.

Further Features in Moldflow 2024

Negative sink marks in 3D calculations

In Moldflow Insight 2024, negative sink marks (dents, embossing lines) can now also be displayed. In addition to the actual sink marks, this can be an important result in the event of overloading, for example.

Technology optimization for core shift

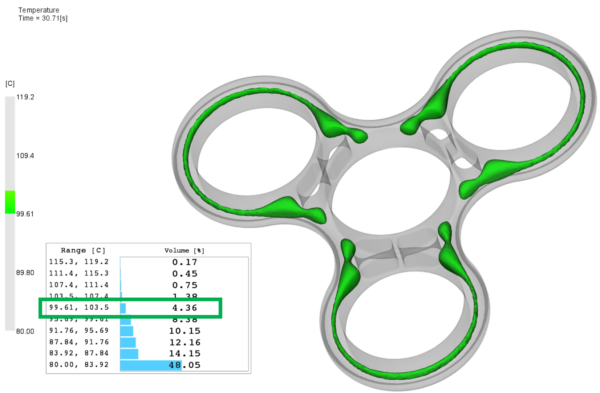

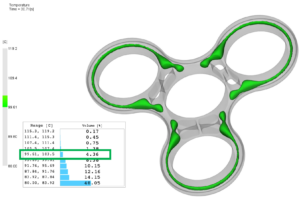

Even better presentation of results

In recent years, further display options and color settings have been added to the results display. The new version now also includes histograms. As in the example image, the display of the plastic soul, for example, has been considerably improved.

What does ‘Named User Licenses’ actually mean in Moldflow?

Moldflow Adviser

- Personalized licenses (account-based)

- Unlimited account switching possible

- Full Adviser Ultimate expansion level

- Additional Fusion 360 + Simulation Extension license included

- Access without VPN

- Reduced license management effort

- Global usage rights

- Access to Moldflow Flex offers (from April 2023)

Moldflow Insight

- Personalized licenses (account-based)

- Unlimited account switching possible

- Full access to all Moldflow technologies

- Additional Fusion 360 license included

- Access without VPN

- Reduced license management effort

- Global usage rights

- Access to Moldflow Flex offers (from April 2023)

List of all major new features:

- Installation and License Management:

- Introducing new installation steps prompting users for license type.

- Network License Manager (NLM) updated to version 11.18, a prerequisite for Moldflow 2024 installation.

- Material Data Updates:

- The material database now updates independently of the software, allowing regular updates without a complete software upgrade.

- A new version of Moldflow Datafitting software for those working on material data adjustments.

- User Interface Updates:

- Update to the Study Duplication feature to enhance UI stability and minimize data corruption.

- Support for the latest versions of Moldflow result files in Moldflow Communicator.

- Solver Updates:

- Improvements to the Dual Domain Warpage Prediction for more accurate results.

- Sink mark predictions for 3D simulations now capture negative sink marks.

- Updated default values for the Molding Window Analysis tool for more realistic process settings.

- Improved accuracy in calculating thermal expansion coefficients for composites with anisotropic matrix properties.

- Moldflow Insight 2024-Specific Updates:

- Introduction of the STAMP model for more precise 3D warp analysis using measured material shrinkage data.

- Enhanced Core Shift Analysis for predicting movements in contact between mold inserts.

- Addition of the “Hot Gate” property to 3D tetrahedral elements.

- Inclusion of physical blowing agents in the chemical foam molding process.

- Consideration of the anisotropic effect of fiber orientation on polymer thermal conductivity and rheology in 3D analyses.

- New visualization options such as Deviation From Part Design and Histogram Plot for improved analysis capabilities.