The new Moldflow 2026 version offers numerous enhancements and improvements that further increase calculation accuracy, accelerate simulation results, and optimize user-friendliness. The highlights are summarized on the following page.

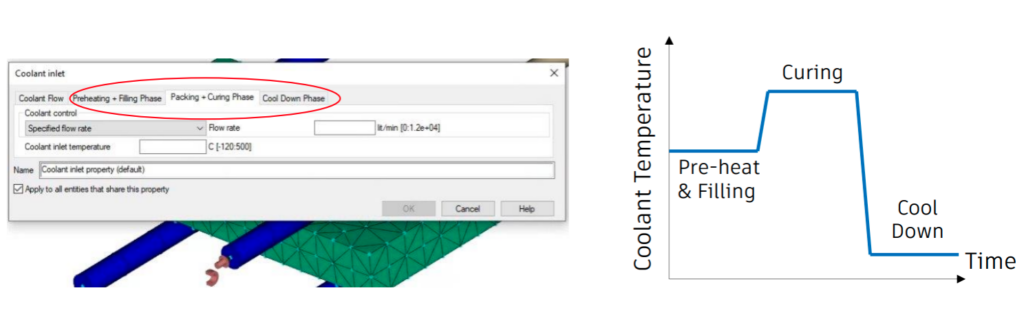

Cool (FEM) Calculations for Resin Transfer Molding Processes

Resin Transfer Molding (RTM) has been available in Moldflow for some time and now offers even more reliable simulation capabilities.

Cool (FEM) for RTM (3D):

Support for various coolant temperatures across different process phases (Preheating, Filling, Curing, Cooling).

Optimized Control:

Customized temperature settings for each phase to enable more precise modeling and analysis.

This enhancement improves thermal process control and provides more detailed results for complex RTM simulations.

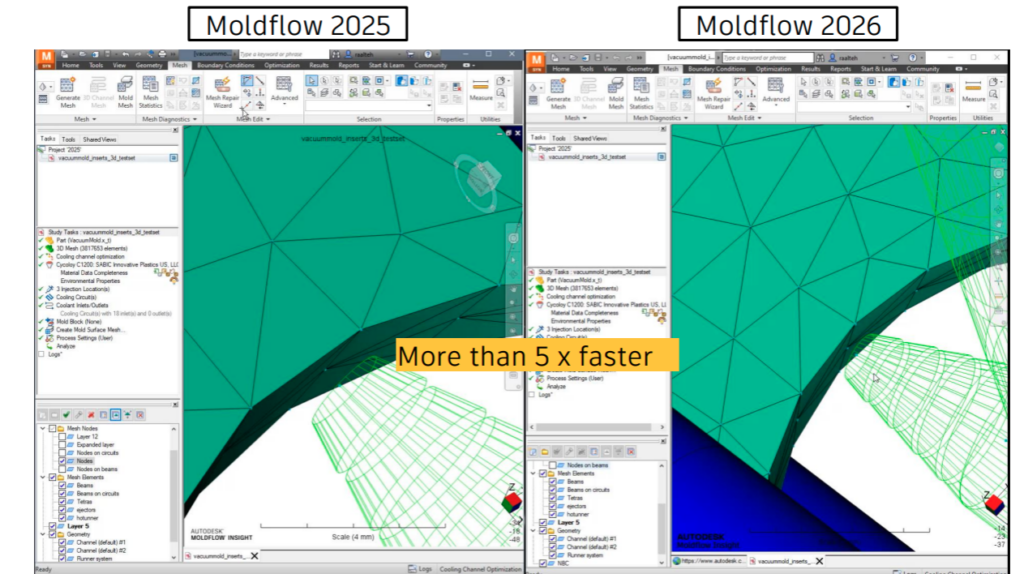

Significant Performance Improvements in Synergy

Moldflow 2026: Even Faster Analysis Times for 3D Models

The latest version of Moldflow introduces substantial speed enhancements for analyzing 3D flow results. Adjustments to the file format optimize both data transfer and computation processes, especially when using external computers.

In addition to these core improvements, 3D warpage analyses are now faster, particularly for larger models, with speed gains ranging from 15% to 25%.

Mesh generation has also been improved:

-

Dual Domain models are now meshed up to 25% faster.

-

3D models are meshed up to 50% faster with higher mesh quality.

These advancements lead to more efficient workflows and improved simulation accuracy.

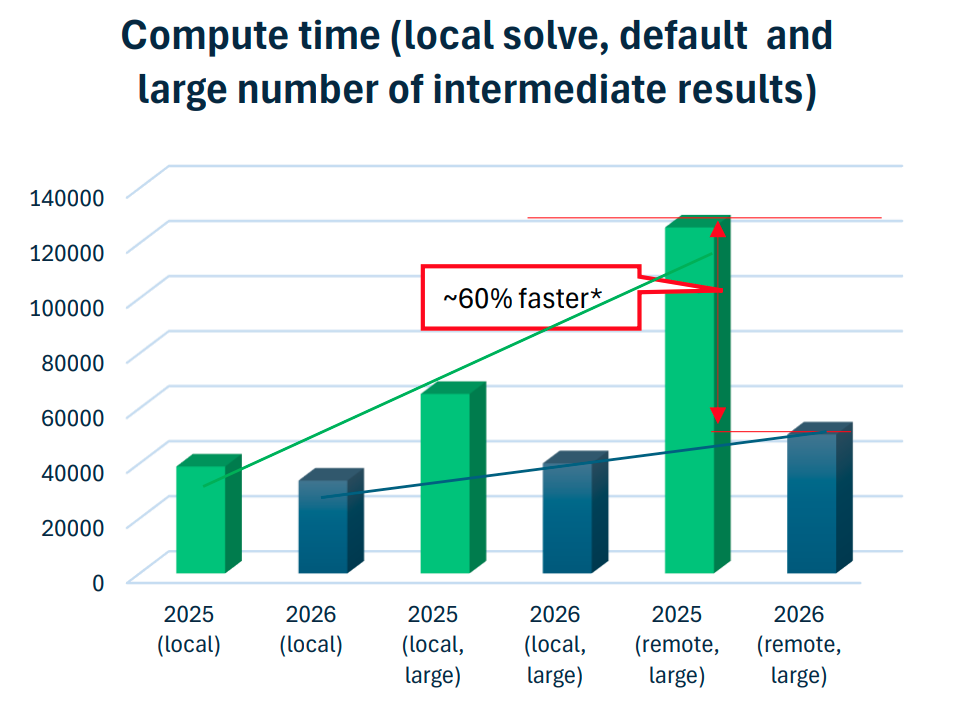

Key Improvements:

-

35% Faster Analysis on Remote Systems: Achieved by reducing data transfer requirements, resulting in significantly improved performance.

-

More Efficient Storage of Intermediate Results: Particularly beneficial for scenarios with numerous intermediate outputs, delivering speed improvements of up to 60%.

-

Reduced Differences Between Local and Remote Calculations: Optimizations ensure that remote analyses are nearly as fast as local computations, enhancing overall efficiency.

With Moldflow 2026, you benefit from significantly improved analysis speed, especially for extensive 3D flow analyses with numerous intermediate results. Boost your efficiency through optimized data processing and reduced computation times!

Moldflow switches to Named-User – what does this mean?

Moldflow Adviser

- Personalized licenses (account-based)

- Unlimited account switching possible

- Full Adviser Ultimate expansion level

- Additional Fusion 360 + Simulation Extension license included

- Access without VPN

- Reduced license management effort

- Global usage rights

- Access to Moldflow Flex offers (from April 2023)

Moldflow Insight

- Personalized licenses (account-based)

- Unlimited account switching possible

- Full access to all Moldflow technologies

- Additional Fusion 360 license included

- Access without VPN

- Reduced license management effort

- Global usage rights

- Access to Moldflow Flex offers (from April 2023)

If you are interested in an update training, simply fill out the form or contact us. Update trainings will be available starting in July.