How to set up Compression Molding Speed

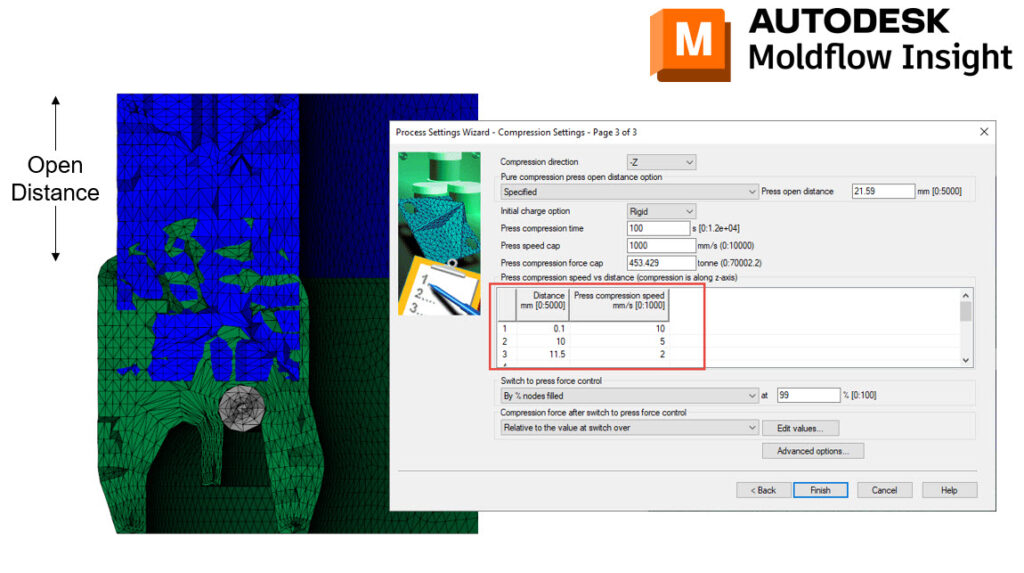

Now that we understand our open distance, let’s talk about setting up our compression speed vs distance.

You might get a process sheet if your compression molding is an existing application. This compression distance might show the entire mold close phase however Moldflow only cares about the open distance (the last 21.59 mm in my example). Therefore, I only need to put in the profile of the mold movement for the last 21.59 mm (NOT the entire mold close phase).

If this is a new application and you do not know the open distance, you can use math to get an approximate fill time. If my open distance is 21.59 mm and I close at 21.59 mm/sec, I will get a 1 sec fill time. If my open distance is 21.59 and I close at 1 mm/sec, I will get a 21.59 sec fill time.

Learn how to perform Compression Molding simulations by visiting our Moldflow Academy Trainings.

How do you set your compression speed vs distance?