Why Automatic Packing in Moldflow Insight is useful!

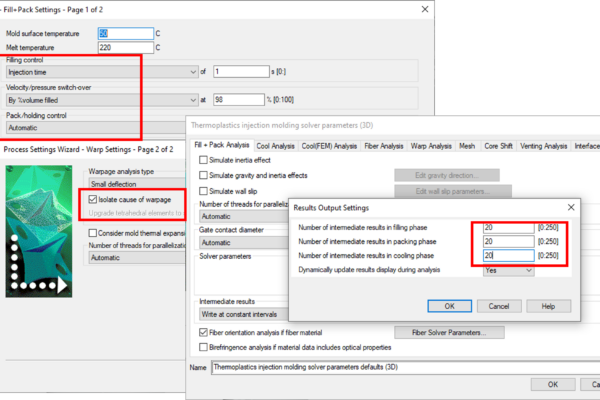

Settings like Filling control, VP Switch-over, and Cooling time – I usually set these explicitly over the Automatics.

Then came version 2021 and the new Automatic Packing feature. This has been great for me as a Moldflow Consultant and is my new default setting for Pack.

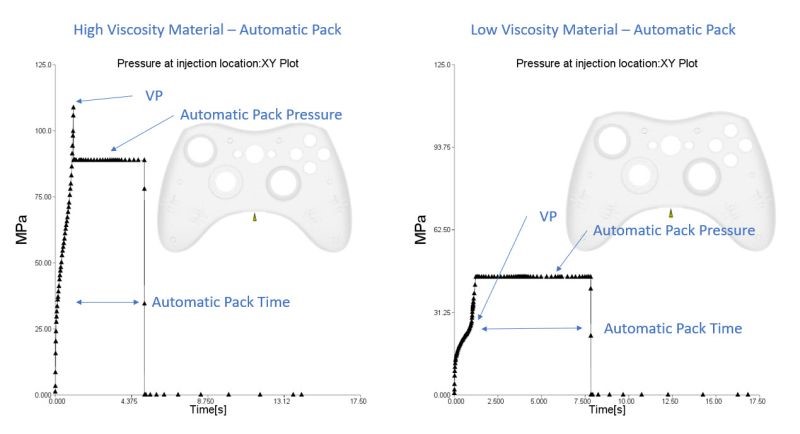

We all know and love the age-old default pack setting of “10 sec @ 80% of Filling Pressure”. While this can be a good starting point, it can also produce some very low pack pressures when the pressure to fill is low (thick part, no runner system, or low viscosity material).

The Automatic Pack would see this low pressure and provide a higher packing pressure that would be more realistic. If the opposite occurs, and Moldflow sees a higher fill pressure, it would reduce it back down closer to the 80% of filling pressure. Best of both worlds.

But wait….there’s more! Automatic packing will also calculate and set your pack TIME! This saves me a full analysis by not having to check when the gate seal occurs, adjusting my pack time, then resolving.

Have you tried the new Automatic Packing in Moldflow Insight (or Moldflow Adviser)?