How to use Moldflow for Powder Injection Molding (PIM)!

One of my college roommates was teasing me about my last post. That made me think of another topic: Powder Injection Molding (PIM)!

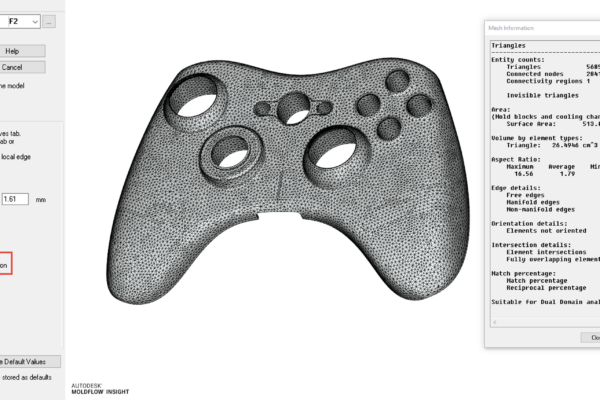

This roommate (let’s call him T-BONE for anonymity) asked me about using Moldflow for PIM a few years ago. I told him sure, send over the model and process settings and I would run it through Moldflow Insight.

What I didn’t tell T-BONE was that I had never used the Powder Metal code within Moldflow. All good – fake it until you make it. What is the worst that could happen, I make a mistake? I have made so many mistakes in Moldflow, I stopped counting years ago.

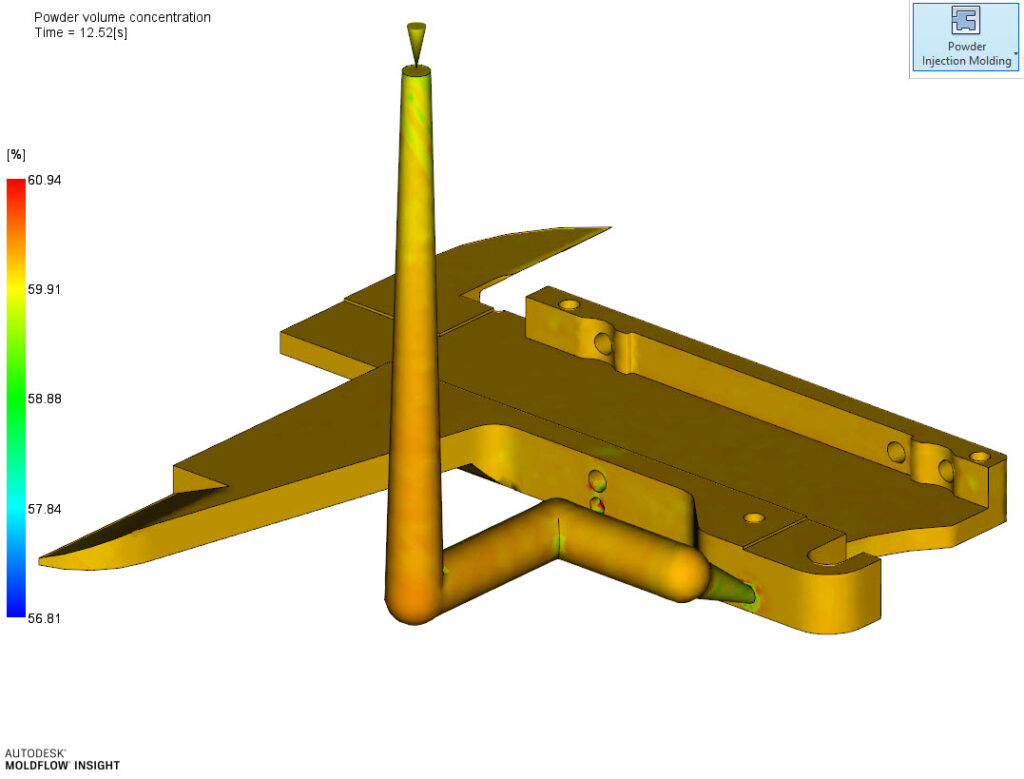

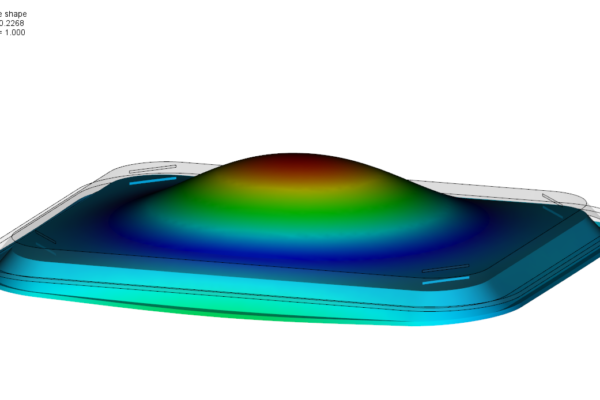

I ran the model through Moldflow Insight and made a sweet report. While sharing with results with T-BONE, I told him that I thought his pack time was too long and the gate froze off at 8 seconds. T-BONE dropped the phone, ran to the press, came back, and said “You are right, pack time is actually 8 seconds”. We reviewed some additional plots around Volumetric Shrinkage, Shear Stress, and Powder Volume Concentration as well.

Lessons learned here?

Tease me about my posts and you will be added to my list of topics

Moldflow can do Powder Metal Injection Molding

Making mistakes in Moldflow is OK! That is how we learn!