How to determine Cure Time for Reactive Molding

What about Cure times? How can we use Moldflow to help us determine cure time?

Cure time is largely thickness, material, and mold temperature dependent. Thin parts with a fast cure package in a hot mold will have lower cure times than thicker parts in a cooler mold.

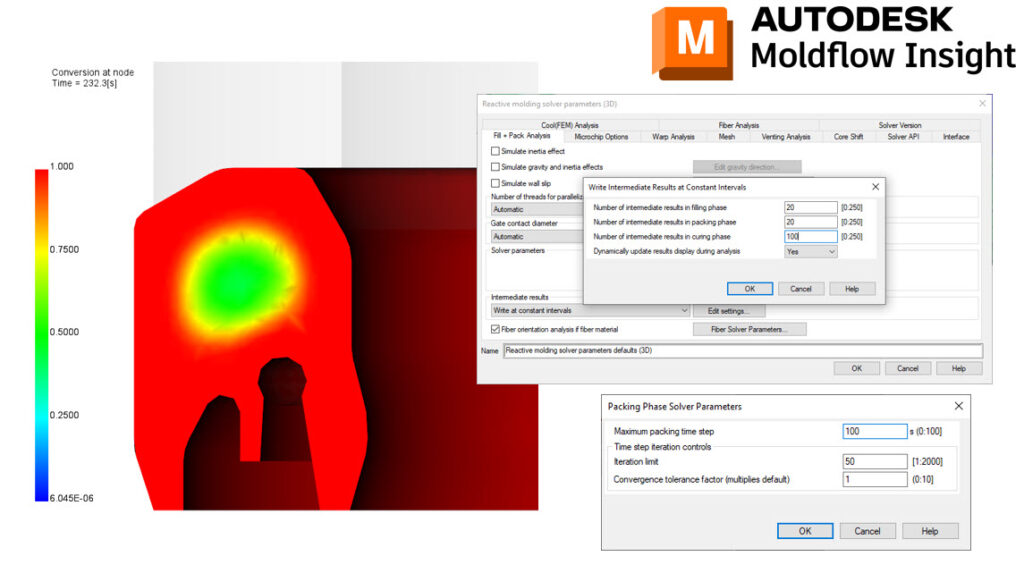

For the first solution in Moldflow, you can simply set the cure time to be high (100 – 300 seconds). If your part is not fully cured, extend the cure time settings. This will solve faster if you leave the default intermediate results settings.

If you have a known, longer cure time target (3-4 hours for example), you might want to increase the number of intermediate results settings to 100 or more. You can also increase your maximum packing time step to 100 sec. This will greatly improve the speed of the solution while still giving you the resolution you need over a 4-hour cure.

Finally, check the Conversion at Node plot to ensure your part reaches full cure.