What is the difference between Mold Temperature and Coolant Inlet Temperature?

I love when I get process sheets that list both Mold Temperature and Water Temperature since these values can be different.

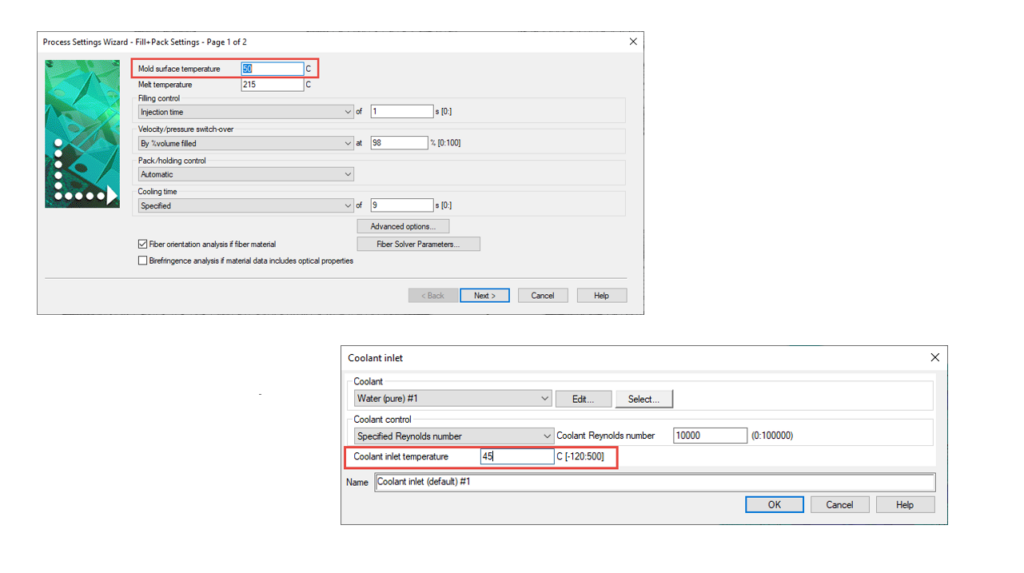

The Mold Temperature values can be used or compared to my isothermal Fill+Pack+Warp while I can use the Water Temperature values for my Cool+Fill+Pack+Warp coolant inlet temperatures.

Depending on the material melt temperature, my target mold temperature, and the cooling line placement, sometimes my coolant inlet temperature differs from my target mold temperature. If I am using HDPE or PP, my coolant temperatures might be lower than my target mold temperatures. If I am using a high-temperature material like PEEK, my coolant temperatures might be closer to the target mold temperature values.

Moral of the story? Coolant inlet temperatures might be different than our mold steel temperatures so plan accordingly.