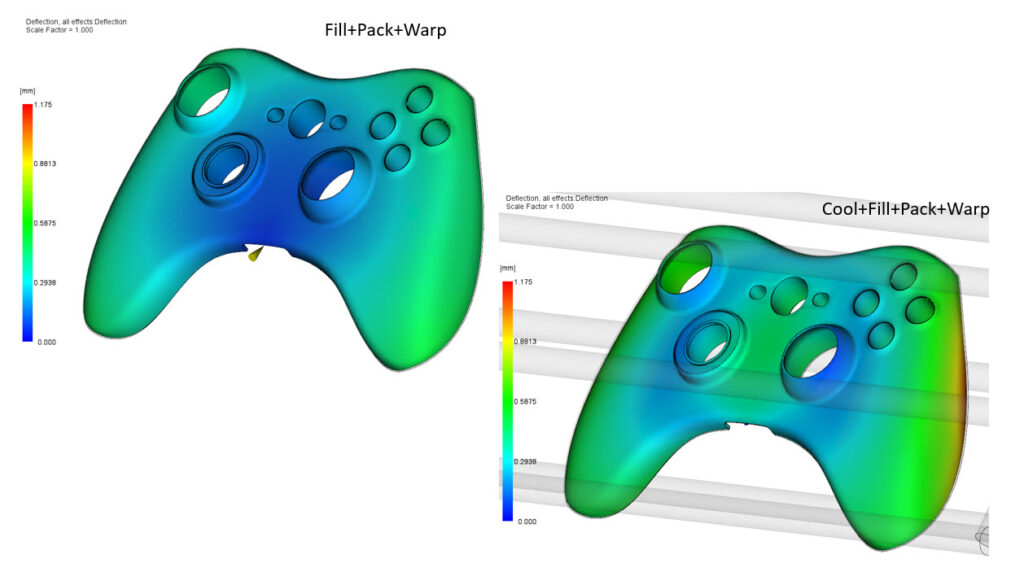

Should we run Fill+Pack+Warp (FPW) or Cool+Fill+Pack+Warp (CFPW)?

I would argue there is a time and place for both. What is the question you are trying to get out of Moldflow?

Running a FPW is an isothermal, single mold temperature simulation. Every surface node and element are seeing the same mold temperature. As long as we understand that assumption, we can look at Warpage under that particular lens. This is a great starting point and a good benchmark to compare against when we start designing our cooling lines.

For my Moldflow Experts out there – Yes I realize that we preach that Cooling should be optimized before Packing and I agree with that philosophy. I also realize how most of our customers actually run Moldflow when I am not looking.

Running a standalone Cool can be faster to help you iterate/optimize or you can run a CFPW to compare your Warp predictions from your isothermal FPW. The Cooling portion would calculate the mold temperature based on your cooling lines, flow rate, mold material, and the plastic melt temperature.

While your CFPW warpage results will never be as good as your FPW warpage results, getting closer to these values means you have a well-designed cooling layout.

Ultimately CFPW will match reality more than FPW, but you have to start somewhere.