The impact that D3 values can have on specific simulations!

I have been avoiding this topic for over a year now…..let’s talk about D3 values.

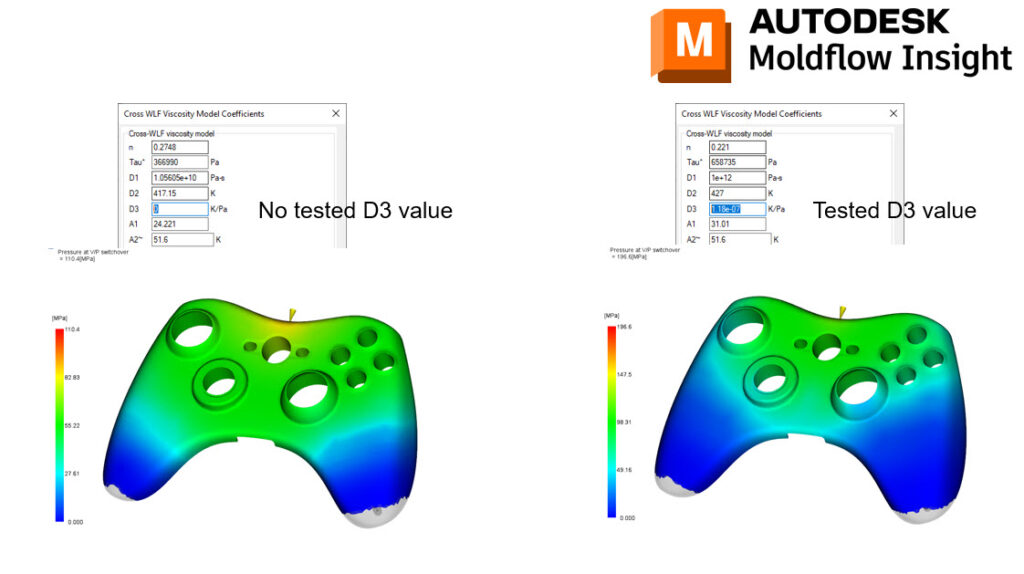

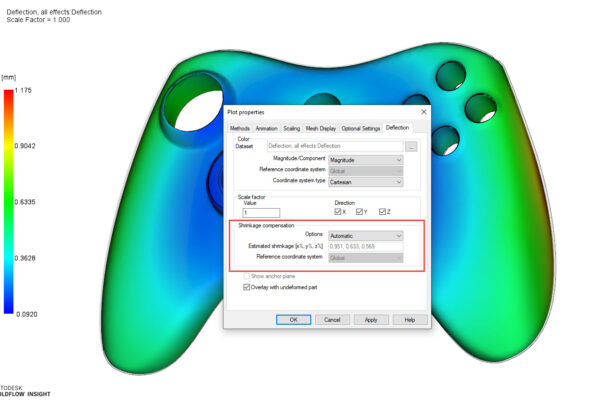

D3 is a value for pressure dependent viscosity within the Cross-WLF viscosity model. Having your material tested for D3 will impact results like pressure. If you have thin-walled parts, high pressure to fill (+100 MPA), or certain materials like Polycarbonate – you should be evaluating your material cards to see if D3 values are present.

These two PC materials have the same Moldflow viscosity index however one was tested for D3 and the other was not. The Pressure at VP Switchover is drastically different between these two studies, mainly due to the D3 values.

PLEASE do not simply add a D3 value at random, this will not yield accurate results. The best solution is to have your material tested or talk to your material suppliers about getting the material cards updated with D3 values.

Were you aware of the impact D3 values have on certain simulations?