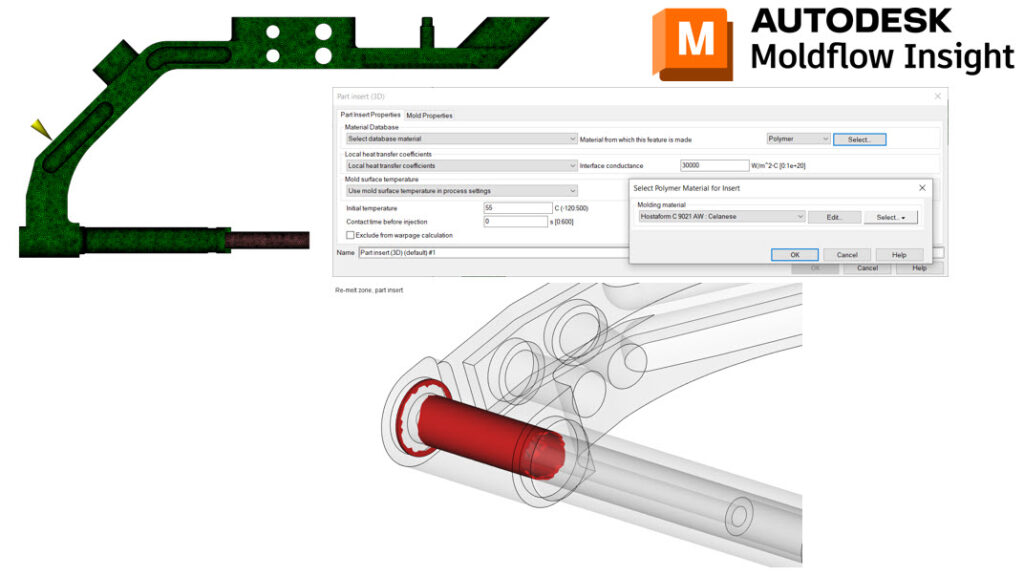

Why the re-melt plot within your analysis can be useful!

Did you know that Moldflow Insight has a Re-melt plot?

This plot will only appear while using a Part Insert 3D in an overmolding analysis or within a Two-Shot overmolding analysis.

The heat from the shot being molded can cause the insert or previous shot to melt, creating this re-melt plot. This can be good for adhesion between the separate parts however too much re-melt can increase the deformation of the insert or previous shot. Also – material that re-melts can potentially start flowing again, leading to optical defects or unwanted movement within molds.

To make sure your parts re-melt sufficiently, have your parts simulated by our engineering office Plastics Engineering Group!

Have you ever noticed the re-melt plot within your analyses?